If you look at modern industrial buildings, colorful roofing tiles, or even the sleek casing of your home appliances, you are likely looking at one specific material. It is durable, versatile, and essential to modern construction.

But what is PPGI?

In this complete guide, we will explore the meaning of Pre-Painted Galvanized Iron, explain the difference between a PPGI coil and a PPGI sheet, and help you understand why this material is the preferred choice for engineers worldwide.

1. What is the Meaning of PPGI?

The acronym PPGI stands for Pre-Painted Galvanized Iron.

While the industry traditionally uses the term “Iron,” it is important to clarify that this actually refers to Steel. To put it simply, PPGI is a galvanized steel product that has been painted (coated) at the factory level before being processed into a finished product.

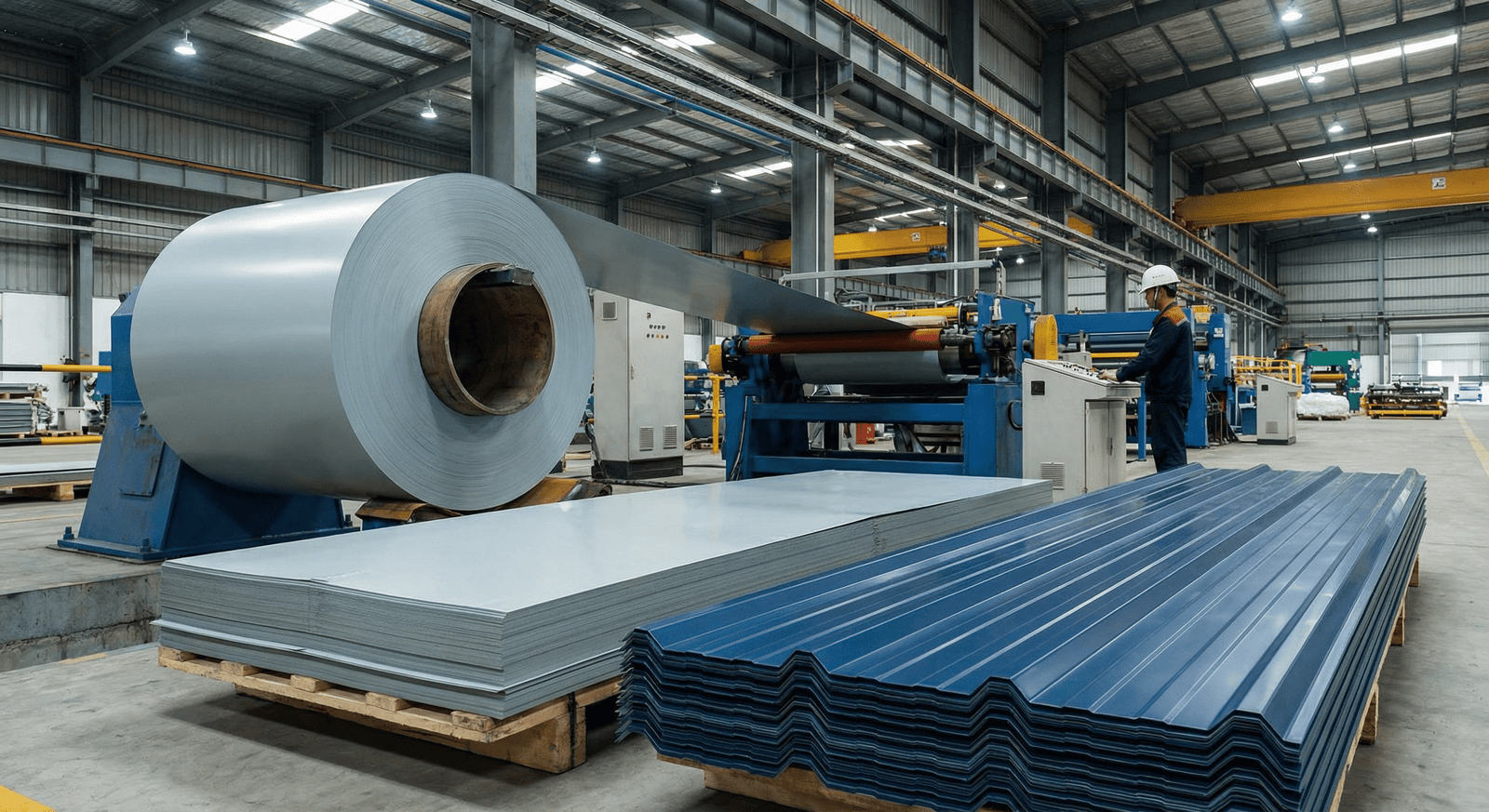

Forms and Availability

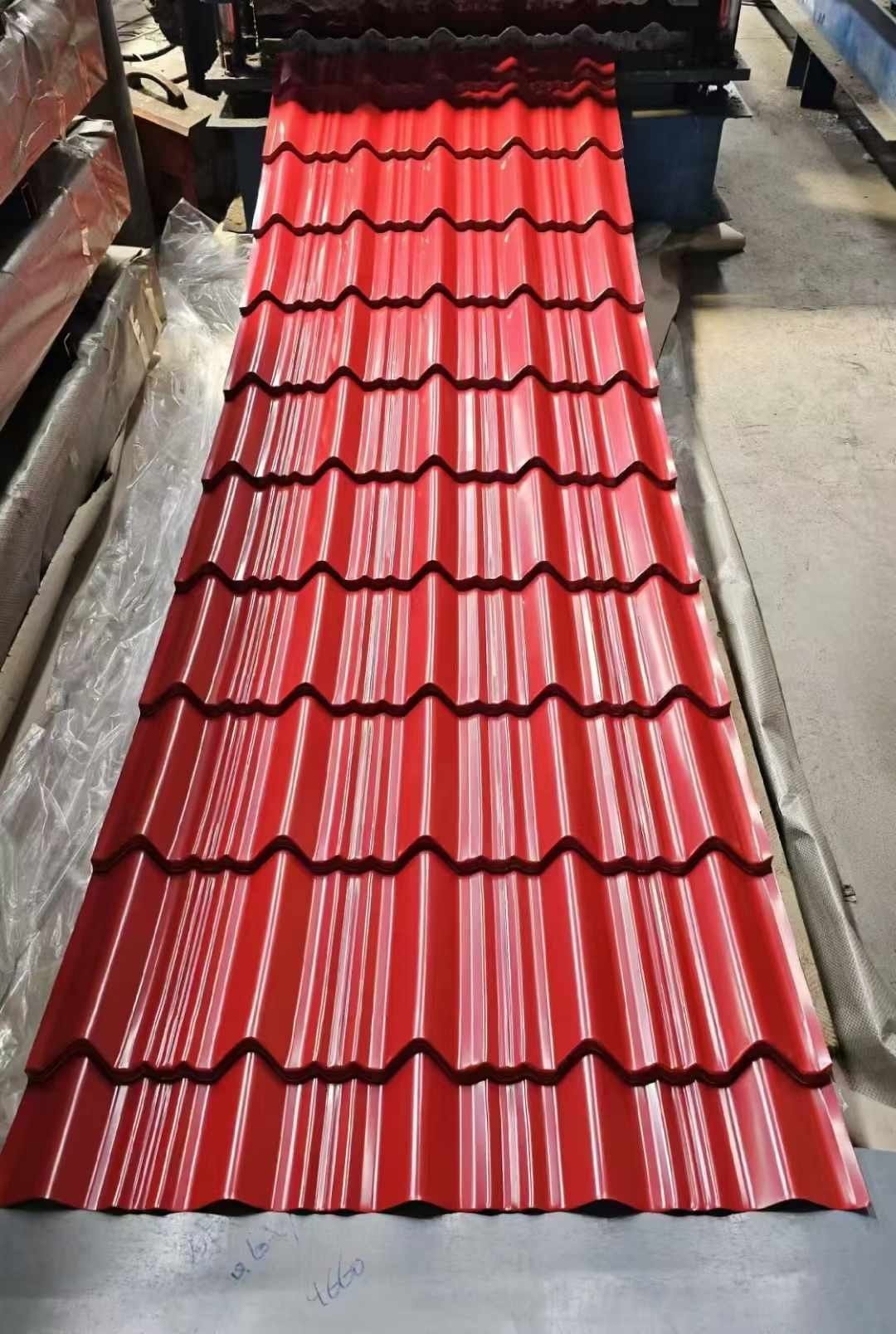

This material is usually manufactured and sold in a continuous roll known as a PPGI coil. This allows for efficient transport and manufacturing. Factories can then unroll the coil to cut it into a flat PPGI sheet or roll-form it into corrugated roofing and wall cladding.

2. How Does PPGI Compare to Galvanized Steel?

One of the most frequent questions we receive from buyers is: How does PPGI compare to galvanized steel?

While both materials start with the same base, they serve different purposes:

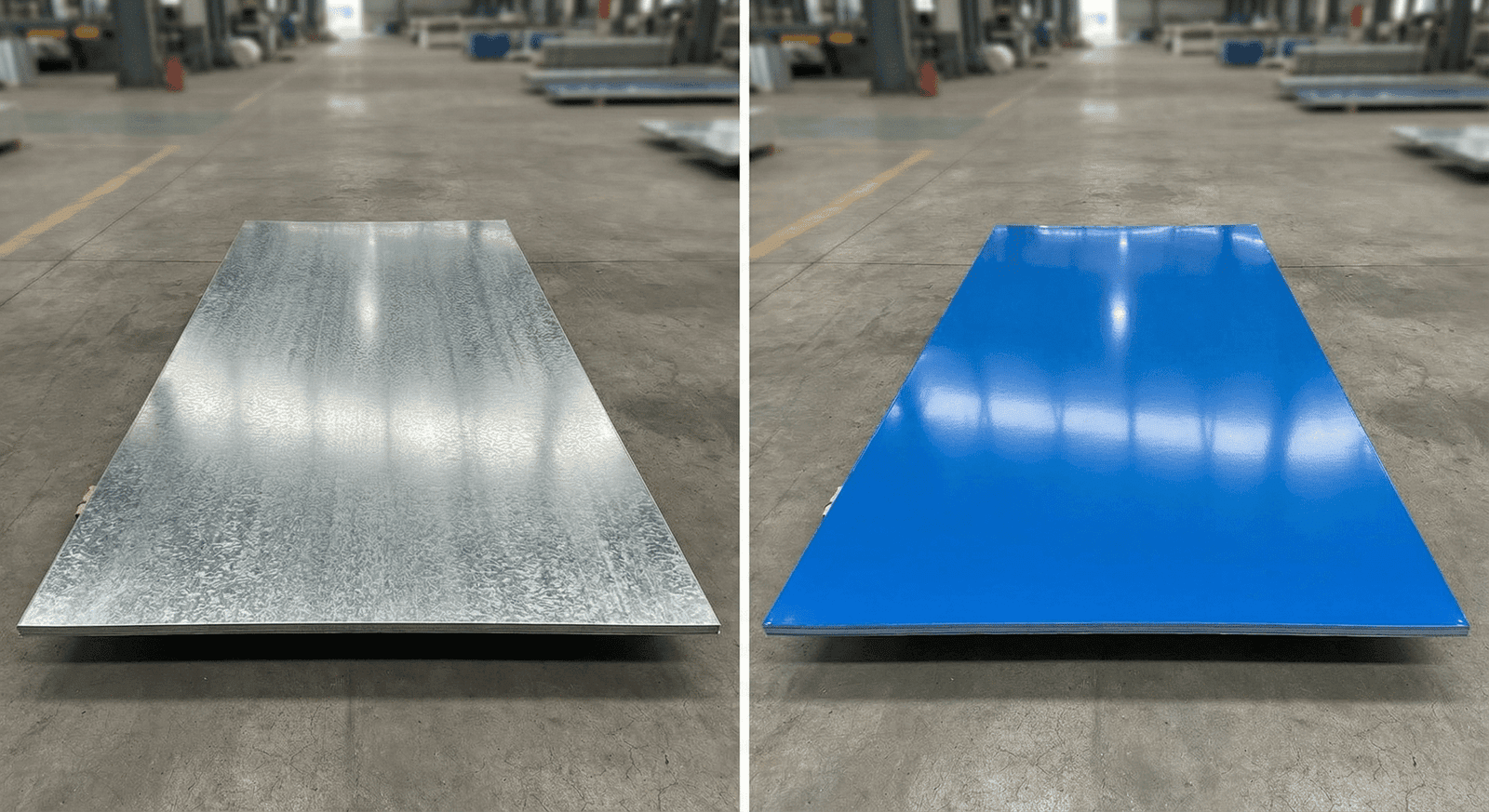

Comparison Point 1: Aesthetics

Galvanized Steel (GI): Features a metallic, silver finish. It often has a “spangle” pattern (zinc crystals) and is typically used for structural components where looks do not matter.

PPGI: Is designed for beauty. It comes in any RAL color, matte finishes, or even printed textures like wood or stone, making it ideal for visible exteriors.

Comparison Point 2: Double Protection

Galvanized Steel: Relies on “Single Protection.” It uses a layer of zinc to stop rust. Once the zinc wears away, the steel corrodes.

PPGI: Offers “Double Protection.” The paint acts as the first barrier against sun and rain. The zinc layer underneath acts as the second barrier.

Comparison Point 3: Durability

Because of the double protection mentioned above, PPGI resists red rust significantly longer than standard galvanized steel in the same environment.

3. The Structure of PPGI: How It Is Made

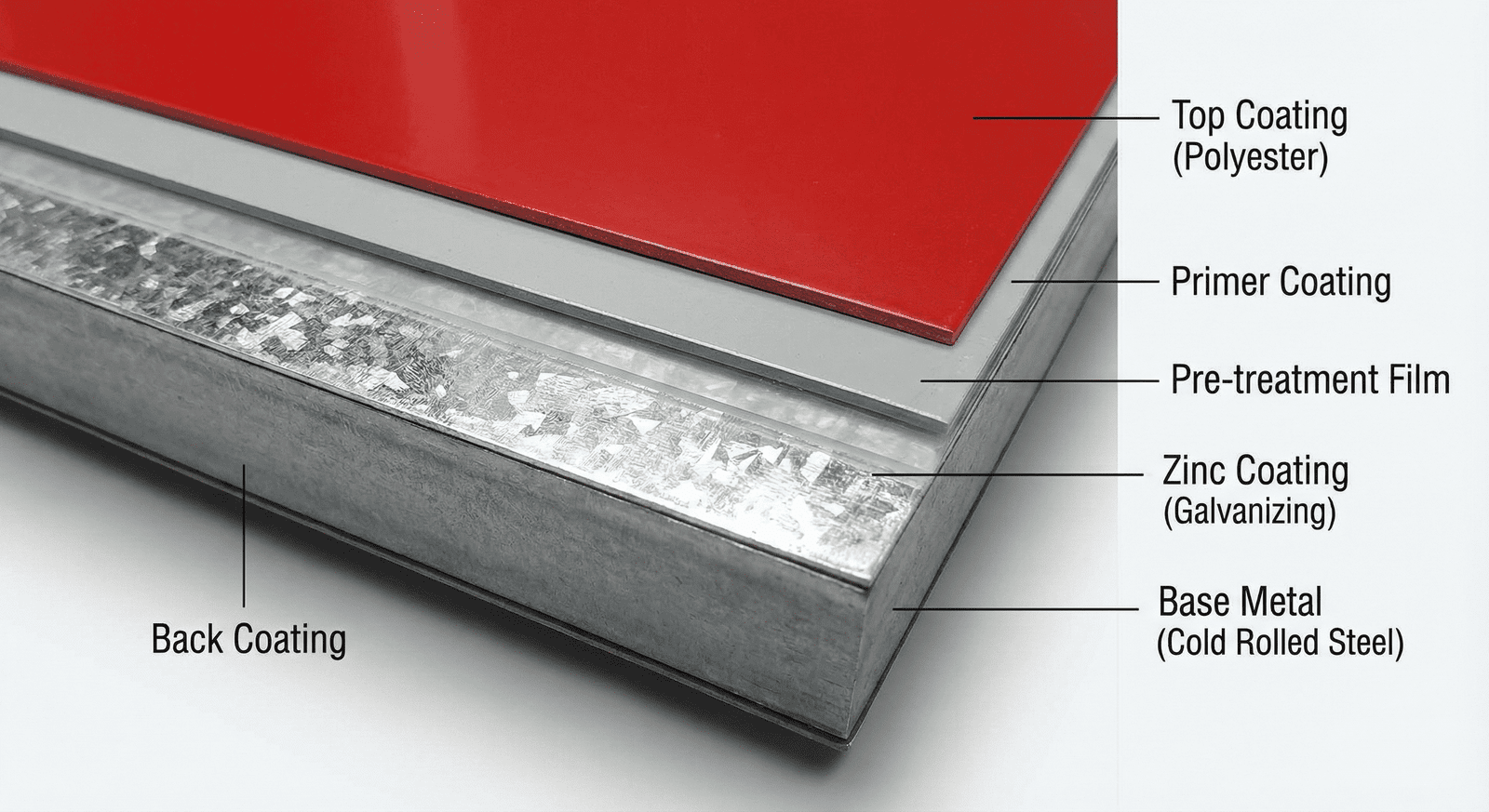

To understand the quality of the product, you must look at the layers. A high-quality PPGI product is effectively a “sandwich” of protective materials designed to withstand the elements.

The layers typically include:

Base Metal: Cold Rolled Steel.

Zinc Coating: The galvanizing layer that provides cathodic protection.

Pre-treatment: A chemical conversion film that ensures adhesion.

Primer: Prevents under-film corrosion.

Top Coating: The final colored paint layer.

4. What is the Life of a PPGI Sheet?

Durability is a major selling point, but what is the life of a PPGI sheet?

Generally, a high-quality PPGI sheet has a lifespan ranging from 10 to 20+ years. However, you cannot determine the lifespan without looking at three critical factors:

Factor A: Paint Coating Type

Polyester (PE): The standard coating for cost-effective projects. Lifespan: 7–10 years.

Silicone Modified Polyester (SMP): Offers better resistance to UV rays and chalking. Lifespan: 10–15 years.

PVDF: The highest quality coating available, used for landmark buildings. Lifespan: 20–25 years.

Factor B: Zinc Thickness

The paint protects the zinc, but the zinc protects the steel. A PPGI sheet with a thin zinc layer (Z40) will rust faster than one with a thick layer (Z275), even if the paint looks the same.

Factor C: The Environment

If the material is used in a dry, inland area, it will last decades. If it is used in a coastal (marine) environment with heavy salt spray, the lifespan decreases unless you use high-grade PVDF paint and thick zinc coating.

5. Choosing the Right PPGI Coil Supplier

Quality control is critical in this industry. A poor production process can lead to paint peeling or color fading within just a few months.

When you are looking for a reliable PPGI coil supplier, ensure they offer transparency regarding:

The Coating Thickness: Can they provide a test report proving the paint thickness (microns)?

The Zinc Mass: Do they adhere to the requested zinc coating weight (e.g., Z100 vs Z40)?

Packaging: Do they use proper vertical or horizontal packaging to prevent moisture damage during shipping?

6. Conclusion

PPGI combines the structural strength of steel with the aesthetic appeal and corrosion resistance of paint. Whether you are building a warehouse roof or manufacturing white goods, choosing the right specifications is key to longevity.

Ready to order? We are a professional factory dedicated to high-quality coating standards. Contact us today to get a quote on your next order of PPGI products.